Trends in Lighting in Electric Vehicles and EV Charging Stations

Introduction

Offering benefits like broad color tuning, programmability, and unique form factors, LEDs are transforming automotive lighting, particularly in the electric vehicle (EV) sector. According to TrendForce, LED headlights, alone, should reach 94% market penetration in the electric vehicle (EV) sector by the end of 2023. It makes sense, given that the high efficiencies and low power requirements of LEDs help address a key challenge of EVs, which is finding ways to expand driving range per charge. That is only part of the story, however. The EV market is a hotbed of innovation, and this is nowhere demonstrated as clearly as in the lighting area. EV designers are using LEDs to improve the driving experience, make vehicles more usable, and increase safety, all while enhancing beauty.

EV Design Evolution

Early EVs mimicked the architecture of internal combustion vehicles, with a central motor in front powering a drivetrain that transferred torque to the wheels. Modern EVs have been radically redesigned. The single forward motor is increasingly replaced by individual motors at each wheel. That eliminates the need for a drivetrain. Without the heat of a forward internal combustion engine, the need for a large, toothy front grill to carry away heat is gone. Changing the architecture makes it possible to change the design – right down to the lighting.

The architectures may have changed but the primary considerations for EV components have not. One of the core design objectives for EV manufacturers is maximizing driving range per charge cycle. That starts with minimizing power consumption, both through the use of highly efficient components and by minimizing vehicle weight. EVs also benefit from highly compact devices, which leave more space in the passenger cabin. Finally, devices need to meet automotive regulatory requirements such as the AEC-Q standard for optoelectronic components in automotive applications (see sidebar).

Sidebar

AEC-Q101 and AEC-Q102 Qualification – a Higher Standard developed and maintained by the Automotive Electronics Council, the AEC–Q standard defines failure-mechanism-based stress testing requirements for optoelectronics in automotive applications. AEC-Q qualification addresses the entire lifecycle of the part, from fabrication through assembly and operation. LEDs and LED assemblies that are qualified to this rigorous standard have demonstrated the ability to deliver reliable performance under a range of challenging conditions, including more extreme temperatures, humidity, voltages and currents. AEC-Q qualification ensures high reliability parts for the ultimate high reliability application.

LEDs Fit the Bill

LEDs provide the ideal lighting solution for automotive applications, particularly for EVs. Key benefits include:

- High efficiency, minimizing power consumption

- Light weight, maximizing charge lifetime

- Ultrasmall sizes, shrinking space claim

- Color changing capabilities, enabling one device to support many requirements

- Programmability, supporting automated functions

- Intelligence, allowing software control, for example through mobile devices

- Reliability, including long lifetimes and failure modes characterized by gradual dimming versus catastrophic failure

- Robustness, to tolerate significant shock and vibration

- DC powered, eliminating the need for DC/AC conversion and the associated losses

To these benefits, add unique form factors that enable lighting design teams to develop innovative solutions that combine attention-getting appearance with enhanced function.

Light Strips and Rope Lights

LED light strips consist of service-mount LEDs and other electronic components preinstalled on narrow, flexible circuit boards (see figure). The LEDs can be white-light LEDs with various correlated color temperatures (CCTs), RGB triads, or RGBW chips. The latter two can be tuned to any shade and luminous flux across the full color gamut. Light strips that incorporate RGB LEDs with a built-in IC enable each LED to be individually addressable and dynamically color tunable in real time.

LED light strips are encapsulated to protect the components and available with IP ratings as high as IP68. That said, they should be protected by an overlay or installed in locations for indirect lighting.

Figure 1: LED light strips consist of narrow, flexible circuit boards populated with surface-mount LEDs of various colors. With a built-in IC, individual RGB LEDs on the light strip will be independently addressable.

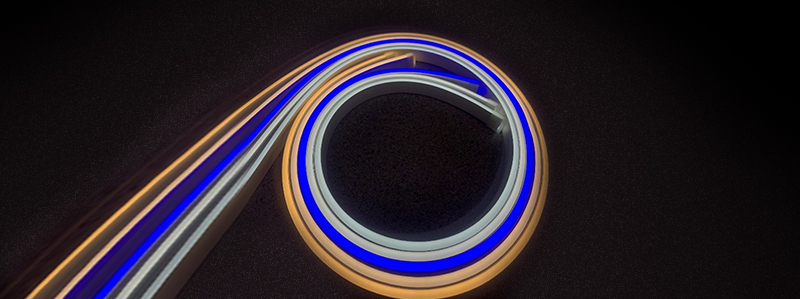

Rope lights are a special type of light strip that encases the LED flexible boards in a silicone tube. The silicone can be clear or mixed with a diffuser (tinted or not) to give a continuous, uniform appearance (see figure).

As with standard light strips, the LEDs can be white light devices with different CCTs, RGB triads, or RGBW chips. With the addition of ICs at each LED, RGB LEDs can be individually addressable. Rope lights are highly flexible, particularly the slide-emitting forms. They’re available with IP68 ratings, making them suitable for outdoor applications such as EV charging stations.

Figure 2: In rope lights, the LEDs are encased in silicone tubes that can be transparent or mixed with diffusing material. Here, too, individual LEDs can be independently addressable and color tuned in real time for sophisticated effects.

Chip on board (COB) LED light strips are another specialized type of light strip. Instead of surface-mount LEDs, COB light strips feature unpackaged LEDs mounted directly to the circuit-board strips using epoxy (see figure). COB light strips are available in white with various CCTs, as well as monochromatic colors with an IP65 rating. They are also available with RGB LEDs with a built-in IC, making each LED color changing and individually addressable. Devices generate high lumen output that is free of hot spots. The combination of high output and flexibility makes them very effective for sinuous designs.

Figure 3: Chip on board (COB) light strips consist of unpackaged LEDs mounted to the flexible circuit board strips. They can generate very high luminous flux densities.

LED PCB Modules

Automotive lighting encompasses headlights, taillights, directional signals, daytime running lamps (DRLs), passenger compartment lighting, functional illumination, indication, instrument backlighting, and display backlighting. The tunability, intelligence, and packaging options of LEDs take EV lighting beyond the humdrum designs of yesterday, adding excitement, sophistication, and enhanced function with minimal effort. The result is a host of new EV lighting trends.

Trend #1: Ambient lighting

With the decentralized architecture of the modern EV, there’s no need for the drivetrain to carry torque from the forward motor to the individual wheels. Getting rid of the drivetrain means getting rid of the motor mound that used to split the vehicle interior. This new sense of openness has inspired EV design teams to speak in terms of living spaces and personal studios rather than passenger compartments. It makes sense that they are also rethinking how they are lighting those spaces.

Ambient lighting is the hottest trend in EV lighting. In this type of nonfunctional lighting, formerly passive areas like the center console, foot wells, armrests, and door pockets are illuminated to play active roles in the driver and passenger experience. LEDs make it possible to go beyond basic white light to add vibrant color that can be dynamically adjusted in real time.

Interior design teams choose materials and textures that will deliver the greatest visual impact with the lowest possible luminous flux and power consumption.

In some cases, drivers choose their color palettes using manual controls or smart phone apps. In other cases, carmakers program combinations of hues created using color therapy research to evoke a desired mood – energetic, calm, reflective, and more. A vehicle may show one color when the door is opened to welcome the driver, and a different chromatic display at the journey’s end. Throughout, the emphasis is on enhancing the driver’s experience.

Trend #2: Safety lighting

The flexibility and intelligence of LED lighting systems equips them to play increasingly important roles in driver and vehicle safety. This is playing out in multiple ways.

The number of vehicle collisions and driver/passenger fatalities rises after dark, despite the fact that fewer vehicles are on the road. The need for improved nighttime visibility has driven the development of adaptive driving beam (ADB) technology. Conventional headlights shine straight ahead at constant brightness. This may be adequate for a straight patch of road with no oncoming cars. But what about curves, side streets, or activities on the shoulder? Here, conventional headlights don’t help much at all. Switching to high beams may illuminate a broader area but at the expense of blinding the drivers of oncoming vehicles or those ahead. ADB headlights provide a solution to this issue.

ADB headlights are designed to modify the light distribution in a way that contributes to safety, either by directing more light to the shoulder of the road preparatory to an upcoming curve or by lowering the brightness for oncoming traffic. All this takes place automatically rather than requiring driver intervention.

Although some versions accomplish these tasks using conventional bulbs repositioned by small, embedded motors, they have only limited range of motion, and the motors add additional points of failure. LED ADB headlights are both more effective and more widely deployed.

LED ADB headlights use very large matrices (up to 100,000) of independently addressable micro LEDs. Each LED in the matrix can be dimmed or full strength as appropriate to create the desired light distribution based on feedback from the vehicle’s forward cameras. They can broaden the area of illumination or direct it toward an upcoming curve. Instead of homogeneously illuminating the entire road ahead, the headlight system selectively dims pixels to reduce glare for drivers of oncoming vehicles or those in the lane ahead. And because the devices are solid state, they are far more reliable than motor-driven designs.

Other LED designs target pedestrian safety. In one system, the headlights flash automatically three times when forward sensors detect a pedestrian in the road. This alerts both the driver and the person on foot of potential danger. A variation on this theme focuses on alerting inattentive drivers. This system integrates the sensors with the ambient lighting system. If the sensor detects that the vehicle remains stationary while the one ahead of it moves away, it will flash the cabin lights aimed at the driver to warn them. The system reacts similarly if sensors detect a pedestrian in the road ahead.

Trend #3: Functional illumination

The ability of light strips to be both independently addressable and programmable opens the way for sophisticated animations that let the vehicle communicate with the driver. In one example, certain ambient lights brighten as the speed of the vehicle rises, warning both passenger and driver. Other animations are used to inform the driver when the vehicle is ready to operate or to track the performance of the vehicle’s speech recognition functions at a glance.

Communications have been extended to taillights. In a number of vehicles, arrays of independently dimmable Mini LEDs let the taillights function for normal signaling while the vehicle is moving but provide alternative information such as vehicle charge level when the motors are idle.

The color-changing capabilities of LEDs enable the same device to double as both daytime running lights and directional signals, reducing power consumption, size, and bill of materials.

Trend #4: Aesthetic lighting

EV design increasingly focuses on a futuristic aesthetic, and that starts with using LED accent lighting. LED strip lights highlight the curves and angles of vehicles on the interior and exterior. LEDs can be used to add an extra level of sophistication to logo treatments, for example.

The move away from front grills has given designers a fresh canvas for their visions. Increasingly, the noses of EVs consist of solid panels accented by EV light strips or bars, or by flexible light strips outlining unique shapes.

The light strip treatment is frequently echoed elsewhere on the vehicle for an integrated design. In one example, a light bar runs across the entire width of the rear of the vehicle, with sections on the ends serving as taillights and turn signals, while the center unit simply provides visual interest that is echoed by stripes across the backs of the side view mirrors.

EV Charging Station Trends

The International Energy Agency projects that by 2030, the number of EVs on the road globally will reach 350 million. Vehicles are not enough, however. They need an EV infrastructure. LED technology has a role to play here, as well.

Although energy efficiency always brings value in terms of reducing the total cost of ownership (TCO), a slightly different mix of benefits makes LEDs appealing for charging stations. Long lifetimes minimize maintenance, once again reducing TCO. LED light strips and modules are available with high IP ratings, a major advantage for charging stations, which are frequently exposed to the elements. Robustness also helps them stand up to the shock and vibration of heavy use.

Trends are emerging in the lighting of EV charging stations, as well.

Trend #1: Functional illumination

Flexible LED light strips enable charging station OEMs to combine innovative aesthetics with indication and functional illumination. In one design, color-changing flexible LED light strips outline the charging station terminal and user screen. The color of the strip changes to indicate progress. If a driver plugs in a vehicle with a low battery, for example, the LEDs start out red, switching to green once charging is complete. The design combines at-a-glance and at-a-distance status updates with striking visual appeal.

Unlike gas pumps, EV charging stations vary widely in design. Functional illumination can guide users through operation. It can be as simple as an indication LED that lights up when the charge cord is plugged in or as sophisticated as a ring of LEDs that switches colors when the charge cable is properly returned to its storage position.

Trend #2: Distinctive styling

As EV infrastructure expands, chains of EV charging stations are springing up. Branding is a necessary part of the process, whether that involves dedicated companies or charging stations at chains of box stores. LED strip lights and modules can be used to create a consistent visual effect. Single LEDs behind graphic overlays can convert logos from ordinary to attention grabbing.

Conclusion

LED lighting is driving innovation in the EV sector. Using LEDs, EV manufacturers are enriching the driver experience through ambient lighting, streamlining communication from vehicle to driver, and increasing safety. Through a combination of innovative form factors and color changing capabilities, LEDs bring increasing levels of sophistication and excitement to vehicle styling. Not to be left out, EV charging station OEMs are also applying LEDs for attention grabbing designs that effortlessly communicate essential information. LEDs provide these benefits while also offering their core advantages of high efficiency, low power consumption, minimal weight, compact form factors, and reliability. Whether for lighting, functional illumination, or indication, LEDs have become a crucial support technology for the EVs and EV infrastructure that are driving us into our transportation future.

American Bright has a comprehensive portfolio of LEDs, LED light strips, rope lights and modules for use in EV interior lighting and EV charging stations. To learn more about our lighting portfolio, including the new AEC-Q102 qualified RGB+IC addressable LED and how it can be designed into your next project, contact us at sales@americanbrightled.com.