Mini-LEDs refer to a newer class of LED (Light Emitting Diode) technology that is smaller than traditional LEDs.

Mini-LEDs are used to create displays with better contrast ratios, brightness, and energy efficiency compared to older LED technologies. To date, mini-LED technology represents the best version of local dimming and black levels in displays, which is particularly beneficial for high dynamic range (HDR) screens.

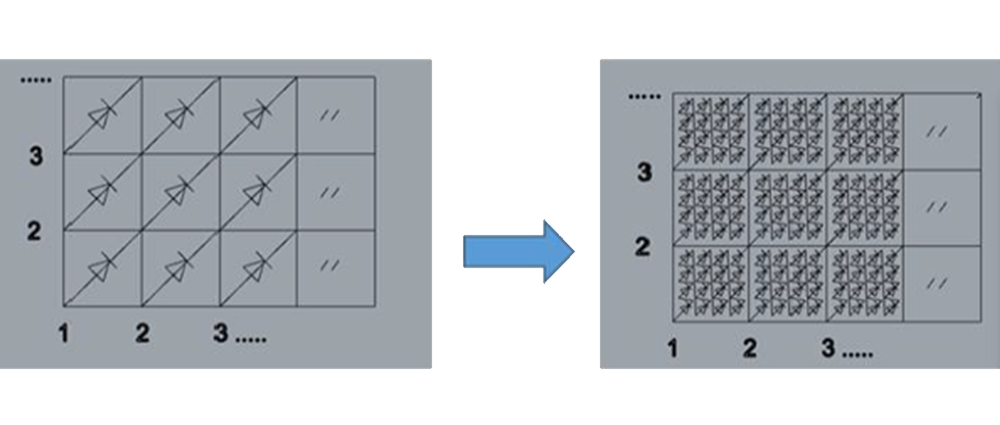

In displays, miniaturized LEDs take the Full Array Local Dimming (FALD) technology a huge step further. Mini-LEDs greatly increase the density, emit more light from each unit, and provide even more precise light control than standard FALD sets.

Traditional LCMs vs. New Mini-LED FALD Displays

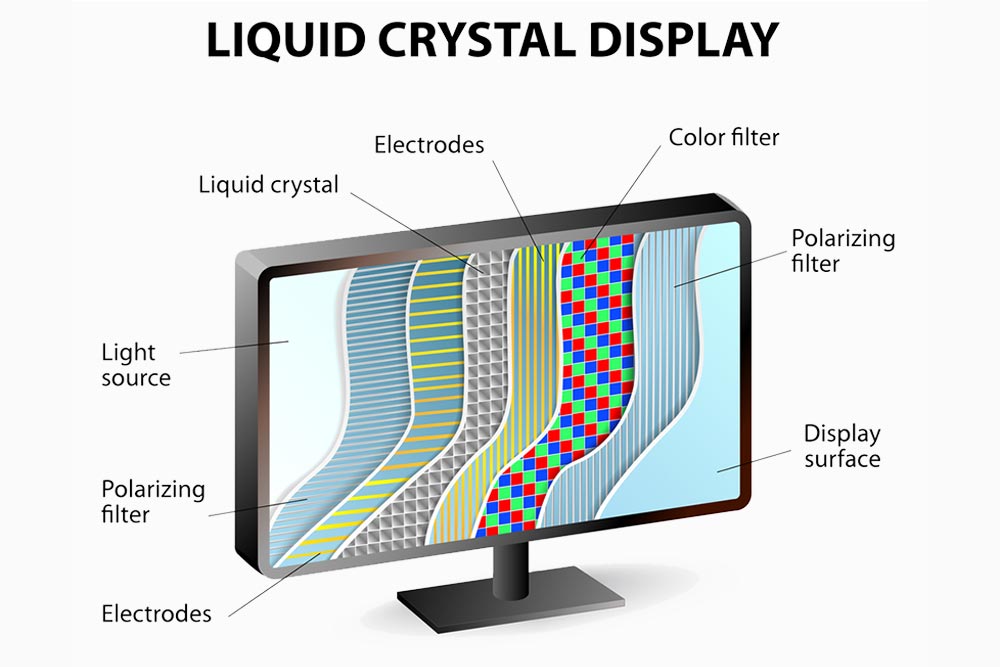

A Liquid Crystal display Module (LCM) can be designed according to the requirements of users by assembling liquid crystal display devices, connectors, integrated circuits, control drive circuits and PCB circuit boards, backlight sources and structural components together.

This use of use of light-modulating properties of liquid crystals combined with polarizers typically takes the form of a flat-panel display. Along with the display of colors, displays employ additional illumination from behind to boost brightness and contrast.

Different Types of Backlighting

Edge Lit

Edge-lit methods use strings of LEDs along the sides of the screen, the top and bottom, or just the bottom, to illuminate the screen. This makes them generally thinner than direct-lit displays. Some edge-lit screens use frame dimming to adjust picture brightness frame by frame, while others use local dimming to darken zones as needed.

Direct Lit

To illuminate the screen directly, this method employs a grid with a small number of LEDs across the entire back of the screen. These LEDs cannot be independently dimmed, however, so contrast is less robust than more advanced backlights.

Full Array with Local Dimming (FALD)

Like a direct-lit display, the backlight of FALD covers the whole back of the screen. The difference lies in the fact that FALD sets use many more LEDs. With new mini-LED technology, this number can grow much larger.

Advantages of Mini-LED Displays vs Traditional LCMs

Higher Brightness Level

- Mini-LED displays are sunlight readable, emitting 3,000 to 20,000 nits. A nit is candela per square meter (CD/mˆ2).

- Traditional LCMs can achieve only 200-400 nits, so often appear dim and illegible in a sunlit room.

- This is good news for all outdoor-screen applications, such as wearable and mobile LCMs, readouts at ATMs, gas stations, and vending machines, as well as window-front retail spaces.

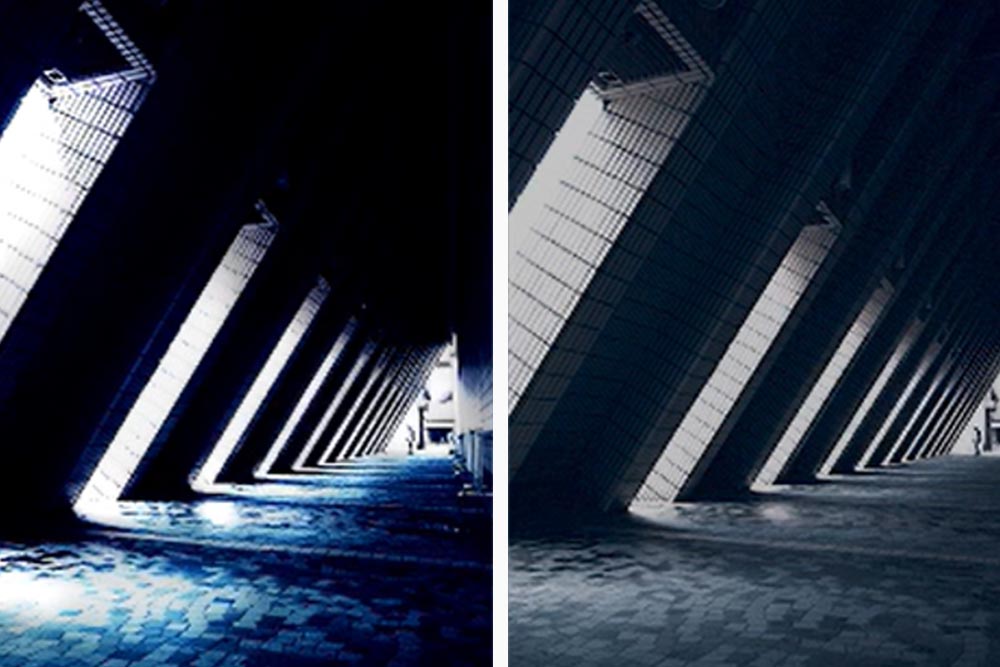

More Agile Local Dimming

- When showing lighter-colored images (white or gray), mini-LED backlight increases the overall brightness of the LCD

- Darker-colored images (black or brown) display with relatively low brightness or no light

One Million-to-One Contrast Ratio

- Local dimming means the effective brightness of each area can be adjusted. Mini-LEDs allow for up to 4096 levels.

- By converting the RGB color scale of each zone into a brightness level, the monitor can adjust the amount of light emitted by each zone to project different brightness levels and achieve better color contrast

- The improved color contrast is 1,000,000:1

Lower Power Consumption

- Since local dimming reduces brightness when the color is black or dark, mini-LED displays can effectively turn-off the LEDs to save unnecessary energy.

- Depending on the color of the content, the energy can be effectively saved by 30-50%.

Lower Operating Temperature

- Heat dissipation is considered in the display design, so thermal effects of extra LEDs do not threaten the stability of the system.

- New systems operate at a temperature less than 50°C, compared to 60 to 70°C.

Longevity

- Given the fact that most of the time the LEDs are only partially illuminated and the overall power consumption is much lower, the product enjoys a longer lifespan.

- Mini-LED displays achieve more than 50,000 hours of operation, compared to 20,000-30,000 hours for traditional LCMs.

What Designers Need to Know When Ordering

American Bright is proud to introduce its new mini-LED display offerings along with all the in-house capabilities of custom manufacturing and product testing. We work closely with customers looking to put the enormous advantages of mini-LEDs and enhanced displays into their projects. Here are some basic guidelines for best practices for designing with mini-LED technology.

Baseline Parameters

These initial specs help to establish the design requirements:

- Size, brand, and model of LCD desired

- Targeted brightness objective (number of nits)

- Quantity of units needed

- Format of incoming signal (HDMI, LCDS, EDP, etc.)

Minimums and Maximums

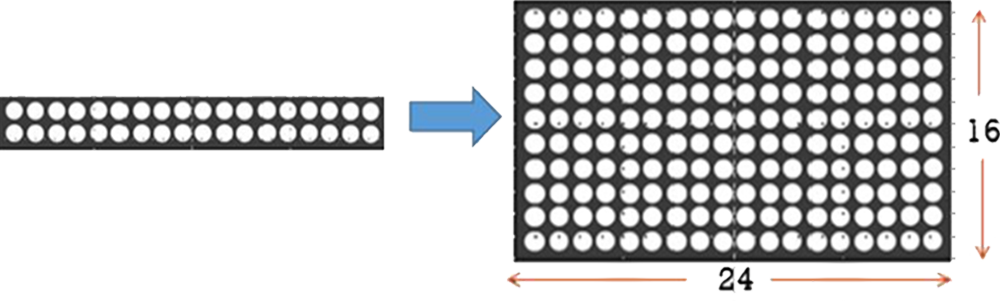

Based on the customer’s needs, the number of LEDs placed varies ranging from 1 to 16 in each zone, from there, we can determine how many blocks are needed based on the overall size of the display. Our standard option is 192/384/768 zones. However, customization is available depending on the size of the LCM chosen.

For example, one board can have anywhere from 1 by 8, or 8 zones, 2 by 8 for 16, up to a maximum of 8 x 48 or 384 zones using a single integrated circuit (IC). If the LCD is large, two boards can also be connected in series via a daisy chain. This means up to 4 boards can be connected in series with a total of 1536 zones.

Lead Times

How long does it take to order a custom display? Lead time can vary between 45 to 90 days depending on the complexity of the design.

Discuss Your Mini-LED Application With American Bright

Now that mini-LEDs have arrived, it is your chance to build amazing displays with a huge improvement in capabilities. With decades of experience designing, manufacturing and testing LED applications, American Bright is here to help bring your ideas to fruition. To get started, talk to one of our technical experts today.